Panel PCs are specialized computers designed for industrial, commercial, and public use. They are typically mounted to a wall or panel, making them ideal for applications where space is limited. These all-in-one systems combine a computer, display monitor, and touch screen into one unit. This makes them well suited for business applications as they offer a sleek design with efficient computing power and easy access to user interfaces.

Benefits of Industrial Panel PCs in Businesses

- One of the main benefits of Panel PCs for businesses is their ability to save on both cost and space.

- They require fewer cables than traditional desktop PCs, resulting in a reduction in installation complexity and associated expenses.

- Additionally, they take up far less desk space than standard desktop computers due to their compact design. This makes Panel PCs an excellent choice for any small business that doesn’t have much room or budget to spare on hardware and accessories.

- Panel PCs can also help improve the efficiency of certain operations within your business. The integrated touch screen provides easy access to user interfaces and applications that otherwise would take longer to access with traditional input devices such as mice or keyboards. This can help speed up processes like point-of-sale transactions or customer service inquiries as users don’t have to navigate through complex menus or instructions when using Panel PCs.

- In addition, Panel PCs can be used in locations where traditional computers cannot be used due to environmental conditions such as extreme temperatures or vibration levels from machinery operation . Most Panel PCs have specialized features that allow them to perform reliably in these settings without suffering any damage over time . Furthermore , since they are designed to handle tough environments , these systems tend to last longer than conventional desktop computers , reducing the need for frequent maintenance costs .

Overall, businesses of all sizes can benefit from using Panel PCs due their cost savings, durability, and usability . By incorporating this technology into their operations, companies have more opportunities to optimize their workflow and increase productivity .

Industrial Panel PCs market growth

Industrial panel PC market is projected to grow at a CAGR of 7.5% from 2023 to 2030. The increasing demand for cost-efficiency, flexible computing power and continuous operation is attributed to the growth in this market over the forecast period. Furthermore, the growing need for touch screen PCs with enhanced safety features has further spurred demand among commercial enterprises in the UK.

Moreover, rising infrastructure investments fueled by government initiatives are expected to bolster opportunities for vendors in this sector over the projected timeframe. Additionally, technological advancements such as Internet of Things (IoT) enabled devices have created potential applications in various industries such as transportation, healthcare and manufacturing which will fuel market growth in future years.

With emerging trends like machine learning and artificial intelligence (AI), vendors are focusing on integrating advanced technologies into their products which will lead to better demand prospects by 2030 and beyond . This expected rise in innovative applications along with wider acceptance of IoT technology is anticipated to drive industrial panel PC sales across Europe during the upcoming decade . Moreover , companies have been continuously expanding their product portfolio by adding new features that could help them gain a competitive edge over others , thereby propelling further growth within this sector . All these factors combined are driving an increased adoption rate of

Different Types of Industrial Panel PCs

There are several different types of Industrial Panel PCs available on the market today. These include standard all-in-one panel PCs, fanless panel PCs, embedded computers, and fully rugged systems.

All-In-One panel PCs

Standard All-In-One panel PCs offer a combination of computing power and user interface in one unit. They typically include a display monitor and touch screen built into the system for easy access to user interfaces without having to use additional input devices such as mice or keyboards. Furthermore, these systems tend to be relatively affordable which makes them an attractive option for businesses with limited budgets.

Fanless Panel PCs

Fanless Panel PCs come equipped with specialized heat sinks that allow them to remain cool without requiring any internal cooling fans – making them an ideal choice for operating in environments where dust or other contamination exists or if there is not enough space within the computer’s case for adequate air circulation. In addition, Giada PC since no moving parts are used they tends to last longer than traditional desktop computers while also consuming less electricity thereby reducing operating costs over time .

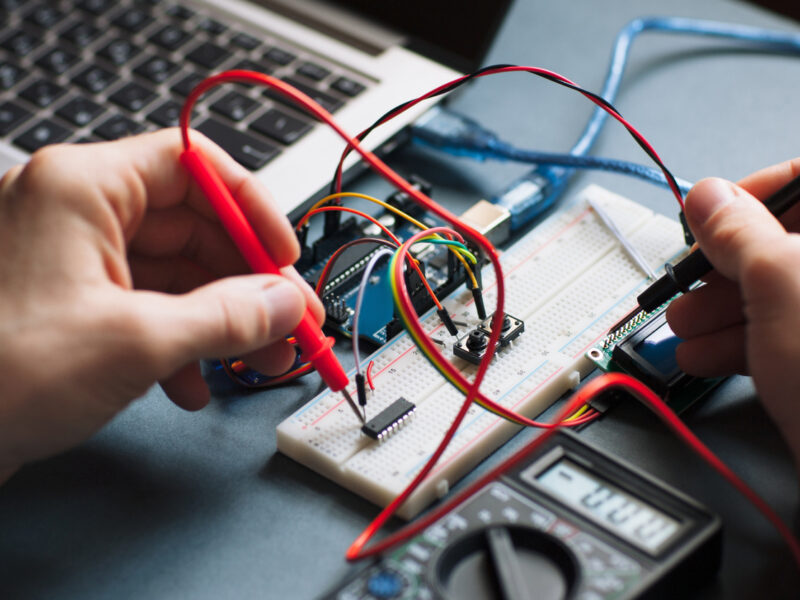

Key factors to consider when selecting an industrial panel PC

When selecting an industrial panel PC, it is important to consider nine key factors.

1. CPU Performance:

The processor is the heart of any computer system and should be selected based on the needs of the application and expected workload. Factors to consider include the number of cores, clock speed, front-side bus speed, cache memory size, thermal design power (TDP), and instruction sets supported. For many applications, Intel Core i3 or i5 processors provide a good balance between performance and cost.

2. Memory Capacity:

To meet application requirements, system memory should be selected carefully according to the requirements of the software being used as well as expected workloads. Ensure that enough RAM is included for optimal multitasking performance and functions such as video playback or image repositories that may require large amounts of RAM.

3. Heat Dissipation:

Industrial panel PCs need sufficient cooling systems in order to ensure reliable operation in high temperatures or dusty environments for extended periods of time. In addition to fan configurations and other cooling mechanisms, consider passively cooled systems with superior heat dissipation capabilities where available.

4. Input/Output Options:

Make sure that your industrial panel PC has all necessary I/O ports including RS232 serial ports, USB connectors, Ethernet connectivity options such as RJ45 jacks or fiber optics connectors, VGA connectors for external displays, audio jacks for headsets or speakers if needed, etc.. Depending on the application type a wide array of optional features may be available including Bluetooth wireless communication technologies or ZigBee mesh networking solutions with integrated antennas on board.

5. Expansion Capabilities:

Consider whether expansion cards are required now or might be needed in future upgrades such as additional I/O ports for specialized equipment connections or communication modules supporting various industrial protocols like CANbus Modbus Profibus etc… Ensure necessary expansion slots are available within the panel PC’s enclosure when selecting hardware components across models from different vendors in order to minimize compatibility issues down the line due to incompatible hardware devices being plugged in later on during operation phases .

6. Long-Term Reliability & Availability:

It is critical to determine whether an industrial panel PC supports long-term availability so it can handle shifting customer requirements over time without any major re-configurations being required while still delivering reliable performance on a daily basis even under stressful conditions. This includes considering environmental factors such as vibration and shock protection ratings along with certifications for specific industries like medical equipment manufacturing facilities to ensure all safety requirements are met at all times .

7. Ease Of Access & Maintenance:

An easy-to-use but robust operating system should be chosen that allows quick access to all functions while providing built-in security features against malicious intrusion attempts . Also make sure that maintenance operations can be carried out with minimal effort using intuitive interfaces and simple troubleshooting tools while avoiding complex procedures that may lead to costly downtime .

8. Size And Weight Requirements:

Depending on where you intend to deploy your industrial panel PC , physical size constraints may become an issue especially when mounting equipment into limited spaces . Make sure that dimensions fit within target areas before making any final purchases as well as bear in mind overall weight restrictions where applicable since some units may become quite heavy due its internal components which could affect mobility if required .

9. Cost Efficiency :

Despite all its advantages , cost must still remain a consideration when selecting an industrial Panel PCs so you don’t eat up too much budget resources unnecessarily by purchasing more powerful hardware than what is actually needed for current operational specifications . Factor in projected growth scenarios so you get a good return on investment while still having enough power reserves left over just in case you need them later down the road if demand rises suddenly due unforeseen circumstances outside your control .